Feature

The kitchenware produced by the cold room die -casting machine has the characteristics of high precision, solid

durability, diverse design, energy saving and environmental protection, and can meet the needs of product

quality, appearance, function and environmental protection in kitchenware manufacturing.

Specification

| LH series of standard parameter table (700 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 7000 |

| Opening stroke | mm | 720 |

| Die thickness(Min--Max) | mm | 350~900 |

| Space between tie bars | mm | 860*860 |

| Ejector stroke | mm | 160 |

| Ejector force | KN | 315 |

| Injection position(0 as center) | mm | 0,-250 |

| Injection force(intensification) | KN | 590 |

| Injection stroke | mm | 700 |

| Plunger diameter | mm | ¢80 ¢90¢100 |

| lnjection weight(aluminum) | Kg | 10 |

| Casting pressure (intensification) | MPa | 117/92/75 |

| Max. casting area(40Mpa) | CM2 | 1750 |

| Injection plunger penetration | mm | 250 |

| Diameter of pressure chamber flange | mm | 165 |

| Height of pressure chamber flange | mm | 15 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 30 |

| Dimensions (L*W*H) | m | 8.4*2.5*3 |

| Machine lifting reference weight | T | 32 |

| Oil tank capacity | L | 1100 |

(Due to the continuous progress of science and technology,the picture,parameter configuration,etc,

will not be changed without notice)

Die casting product

Common types and characteristics of die -casting kitchen utensils:

1. Crystal aluminum kitchenware: Aluminum cast aluminum is a common die -casting kitchen utensil material.

Because aluminum has good thermal conductivity and lightweight characteristics, it makes die casting aluminum

kitchen utensils heated evenly and easy to carry during the cooking process. This type of kitchen utensils usually

include pots, flat pots, fried pan, etc.

2. wear -resistant kitchen utensils: die -casting technology can create a pot with high wear resistance, such as

a pot made of hard anody alumina. The surface of these kitchenware is specially treated, which can resist

scratches and corrosion, and extend the service life.

3. Non -stick kitchen utensils: die -casting technology is also often used to produce non-stick coating kitchen

utensils, such as non -stick pan and non -stick frying pan. During the die -casting process, special non-stick

coatings can be applied on the surface of the kitchen utensils to make the food not easy to adhere and easy

to clean.

4. Multifunctional kitchenware: some die -casting kitchen utensils are designed as multi -functional products,

such as combined pots, stir -fried pots and stew cookers. These kitchenware structures are complicated, and

the overall molding can be achieved through die casting technology to improve the stability and durability

of the product.

5. Beautiful design: Die cast technology can create a complex and smooth kitchenware products, making its

appearance more beautiful and modern. Die -casting kitchenware usually has a solid structure and smooth

surface, which is easy to clean and maintain.

ABOUT US

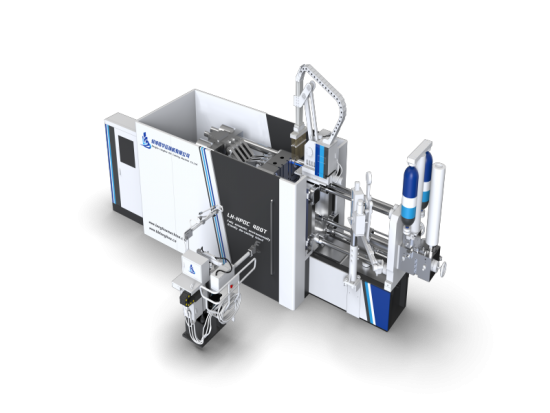

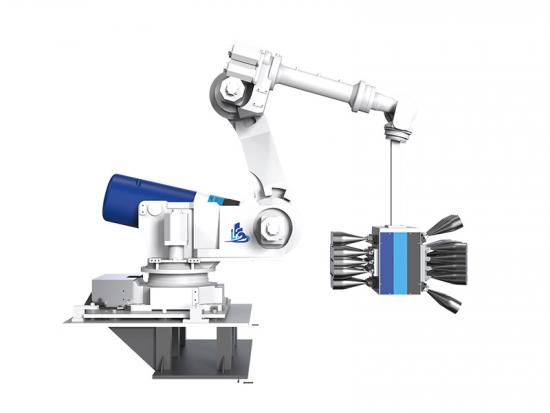

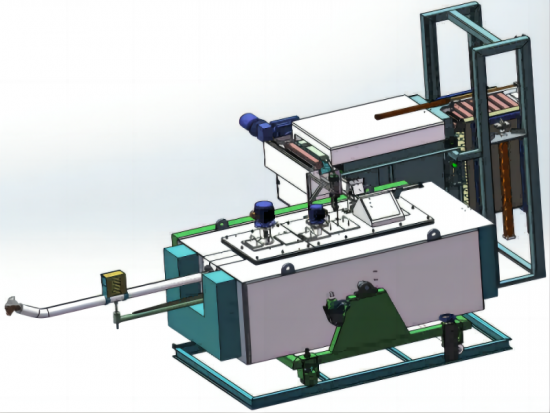

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.

It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for

several decades.The company focuses on research,development,production,and sales of various types of

die casting machines.The company's product range covers cold chamber die-casting machines,die-casting

manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of

different customers.

CE certificate