Product Details

The cold chamber die-casting machine is efficient, precise, and suitable for complex structures when producing

metal products such as door handles, and can meet the production needs of high-quality products.

Feature

The production of die-cast door handles on cold chamber die-casting machines has the following characteristics:

1. High-precision mold design: Cold chamber die-casting machines are usually equipped with high-precision molds,

which can ensure that the size, shape and surface quality of the door handle meet the requirements. These molds

are well designed to ensure high quality products.

2. Rapid cooling: The cold chamber die casting machine is equipped with a cooling system that can quickly reduce

the temperature after the metal fills the mold, prompting the metal to solidify quickly. This can shorten the

production cycle and improve production efficiency.

3. Suitable for high melting point metals: Cold chamber die casting machines are usually suitable for producing

door handles of high melting point metals such as aluminum alloys, magnesium alloys, etc. These metals require

faster cooling after heating to maintain their ideal physical properties, and cold chamber die casting machines can

provide such a processing environment.

4. Optimized die-casting process control: The cold chamber die-casting machine is equipped with an advanced

control system that can accurately control process parameters such as metal injection pressure, injection speed,

and cooling time. Precise control of these parameters ensures the production of high-quality, consistent door

handle products.

5. Suitable for complex structures: Cold chamber die casting machines can produce door handles with complex

structures, because cold chamber die casting technology can provide better metal fluidity and filling properties,

making it easier to produce complex-shaped products.

6. Environmental protection and energy saving: Cold chamber die casting machines usually have high energy

utilization and low scrap rates, which help reduce energy consumption and material waste and comply with

environmental protection requirements.

Specification

| LH series of standard parameter table (500 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 5000 |

| Opening stroke | mm | 580 |

| Die thickness(Min--Max) | mm | 350~850 |

| Space between tie bars | mm | 760*760 |

| Ejector stroke | mm | 140 |

| Ejector force | KN | 250 |

| Injection position(0 as center) | mm | 0,-220 |

| Injection force(intensification) | KN | 480 |

| Injection stroke | mm | 580 |

| Plunger diameter | mm | ¢70 ¢80 ¢90 |

| lnjection weight(aluminum) | Kg | 7 |

| Casting pressure (intensification) | MPa | 175/200/250 |

| Max. casting area(40Mpa) | CM2 | 1250 |

| Injection plunger penetration | mm | 250 |

| Diameter of pressure chamber flange | mm | 130 |

| Height of pressure chamber flange | mm | 15 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 22 |

| Dimensions (L*W*H) | m | 7.75*2.28*3.14 |

| Machine lifting reference weight | T | 22 |

| Oil tank capacity | L | 1000 |

(Due to the continuous progress of science and technology,the picture,parameter configuration,etc,

will not be changed without notice)

Die casting product

Common die-cast door handle types and their characteristics:

Cast aluminum door handles: Cast aluminum is one of the common materials used to make die-cast door handles.

Aluminum is lightweight, corrosion-resistant, and strong, making it suitable for door handle manufacturing. This

type of door handle usually has a simple design and smooth surface, and is suitable for use on a variety of

indoor and outdoor doors.

Decorative door handles: Some die-cast door handles are designed as decorative door handles with a beautiful

appearance and unique design. These doorknobs are usually used for interior doors or decorative doors to

enhance the overall beauty of the door and match the interior decoration style.

Utility door handles: Other die-cast door handles are designed as utility door handles, which are sturdy and

durable and suitable for industrial locations or doors that need to be opened and closed frequently. These door

handles typically feature sturdy construction and ergonomic designs for user convenience and long-term reliability.

Outdoor door handles: Outdoor door handles usually need to be rust-proof, weather-resistant and corrosion-resistant

to adapt to various harsh climate conditions. Die-cast door handles can achieve these properties through special

surface treatments or material selections, making them suitable for outdoor door use.

Modern design door handles: With the development of the times, modern design door handles are becoming more

and more popular. These door handles usually feature a simple, smooth design that matches modern architecture

and decoration styles, adding a stylish touch to the overall appearance of the door.

ABOUT US

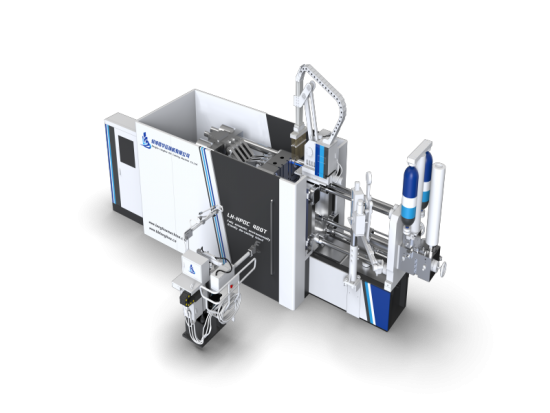

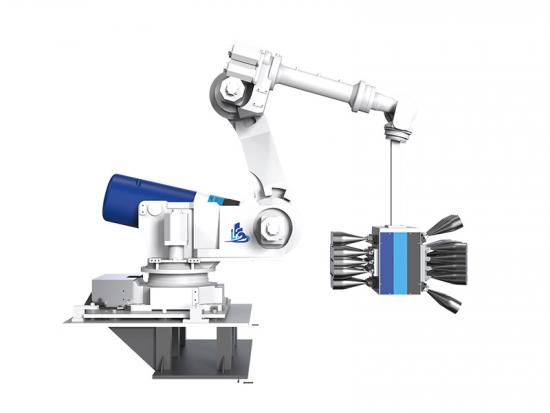

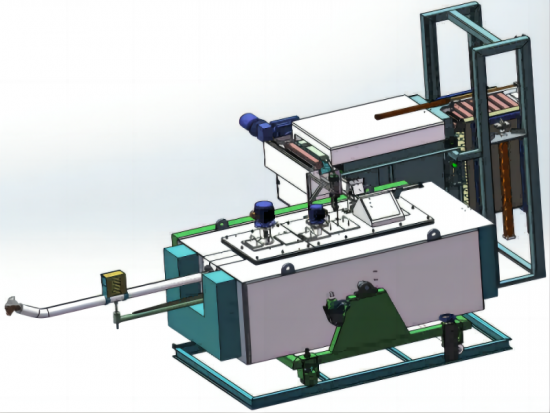

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.

It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for

several decades.The company focuses on research,development,production,and sales of various types of

die casting machines.The company's product range covers cold chamber die-casting machines,die-casting

manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of

different customers.

CE certificate