Feature

LH series of standard parameter table (200 t)

ITEMS

Unit

Specification

Clamping Force

KN

2000

Opening stroke

mm

380

Die thickness(Min--Max)

mm

200~550

Space between tie bars

mm

480*480

Ejector stroke

mm

80

Ejector force

KN

110

Injection position(0 as center)

mm

0,-140

Injection force(intensification)

KN

270

Injection stroke

mm

350

Plunger diameter

mm

¢50 ¢60 ¢70

lnjection weight(aluminum)

Kg

2.4

Casting pressure (intensification)

MPa

135/93

Max. casting area(40Mpa)

CM2

500

Injection plunger penetration

mm

135

Diameter of pressure chamber flange

mm

110

Height of pressure chamber flange

mm

10

Max.working pressure

MPa

14

Motor power

Kw

11

Dimensions (L*W*H)

m

5.32*1.6*2.35

Machine lifting reference weight

T

7.5

Oil tank capacity

L

600

will not be changed without notice)

Features of small copper castings:

1. Good electrical and thermal conductivity: Copper is an excellent electrical and thermal conductive material,

so small copper castings have good electrical and thermal conductivity and are suitable for applications that

require conduction of current or heat.

2. Excellent processability: Copper has good processability. Small copper castings are easy to process such as

cutting, milling, stamping, etc., making it easy to manufacture copper parts of various shapes and sizes.

3. Corrosion resistance: Copper has good corrosion resistance. Small copper castings can maintain stable

performance in humid or corrosive environments and are suitable for occasions that require long-term use.

4. High strength and hardness: Although the hardness of copper is relatively low, the strength and hardness

of small copper castings can be improved through appropriate processing or alloying to meet the needs of

different applications.

5. Beautiful appearance: Copper has metallic luster and good surface treatment properties. Small copper

castings can present a beautiful appearance after surface treatment, and are suitable for highly decorative

products.

6. Environmental protection: Copper is a green material that can be recycled and reused. The

manufacturing process of small copper castings is relatively environmentally friendly and meets

modern environmental protection requirements.

7. Moderate cost: The price of copper is relatively stable, and the manufacturing cost of small

copper castings is generally relatively moderate, making it suitable for various applications with

strict cost control.

8. Diversity and flexibility: Small copper castings can produce parts of various shapes and sizes,

with a high degree of design freedom and can meet the design requirements of different products.

ABOUT US

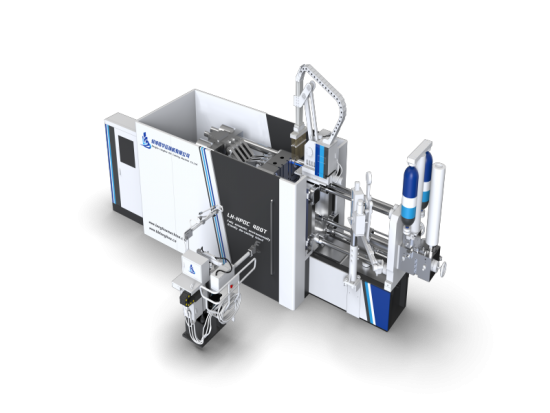

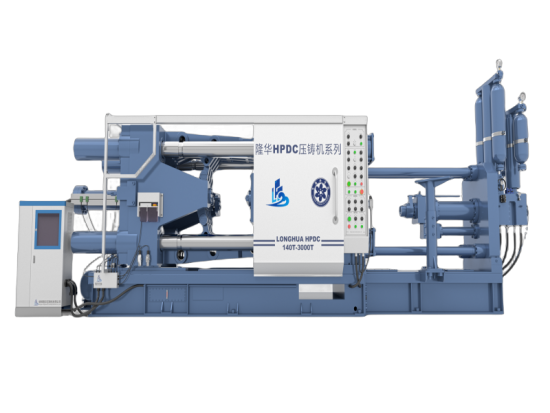

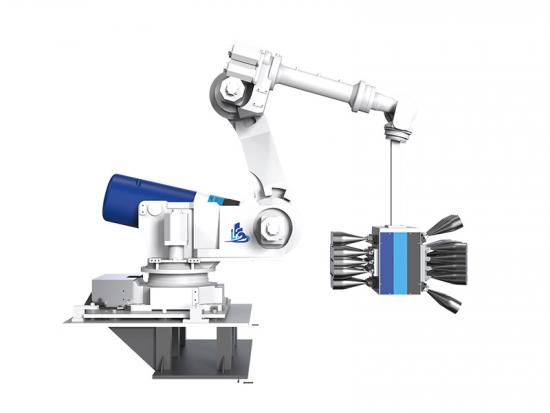

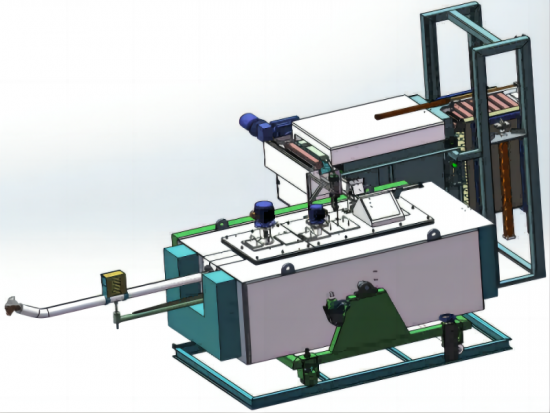

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,

China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting

industry for several decades.The company focuses on research,development,production,and

sales of various types of die casting machines.The company's product range covers cold chamber

die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of

die-casting machines to meet the needs of different customers.