Feature

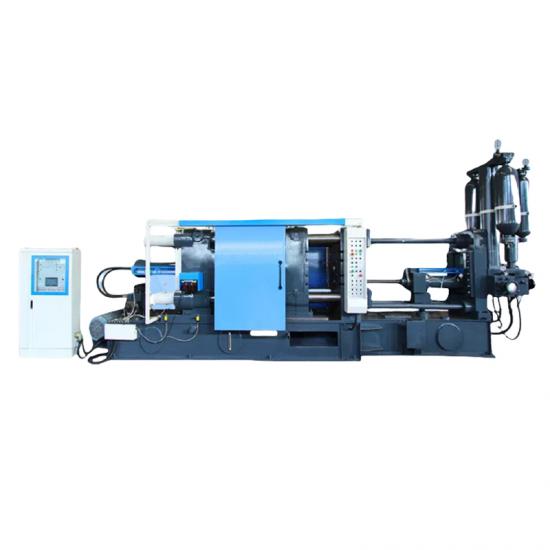

Features of radiator die casting machine:

1. Efficient production: The radiator die-casting machine can efficiently carry out large-scale production, and

through automated processes, can continuously produce high-quality radiator products.

2. Precise molding: The die-casting machine can quickly inject metal materials into the mold under high pressure,

making the radiator molding with high precision and stable dimensions.

3. Material diversity: These die-casting machines are usually able to process various metal alloys, such as aluminum

alloys, copper alloys, etc., allowing the produced radiators to have different performance characteristics and uses.

4. Save materials: Due to the die-casting process, the radiator die-casting machine can minimize the waste of

materials and improve material utilization.

5. Durability: Die-casting machines are usually made of high-strength metal materials, which have strong wear

resistance and corrosion resistance and can operate stably for a long time.

6. Automated control: Most radiator die-casting machines are equipped with advanced automated control

systems, which can monitor and adjust the production process, improving production efficiency and product

quality stability.

7. Energy saving and environmental protection: Compared with traditional processing methods, the die-casting

machine can reduce energy consumption and waste emissions during the production process, and has certain

advantages in energy saving and environmental protection.

Specification

| LH series of standard parameter table (1250 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 12500 |

| Opening stroke | mm | 1000 |

| Die thickness(Min--Max) | mm | 450~1180 |

| Space between tie bars | mm | 1100*1100 |

| Ejector stroke | mm | 200 |

| Ejector force | KN | 570 |

| Injection position(0 as center) | mm | -160,-320 |

| Injection force(intensification) | KN | 1075 |

| Injection stroke | mm | 880 |

| Plunger diameter | mm | ¢100-¢140 |

| lnjection weight(aluminum) | Kg | 25.4 |

| Casting pressure (intensification) | MPa | 137/70 |

| Max. casting area(40Mpa) | CM2 | 3125 |

| Injection plunger penetration | mm | 320 |

| Diameter of pressure chamber flange | mm | 240 |

| Height of pressure chamber flange | mm | 25 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 30*2 |

| Dimensions (L*W*H) | m | 11.3*4.3*4.5 |

| Machine lifting reference weight | T | 80 |

| Oil tank capacity | L | 3000 |

(Due to the continuous progress of science and technology,the picture,parameter configuration,etc.

will not be changed without notice)

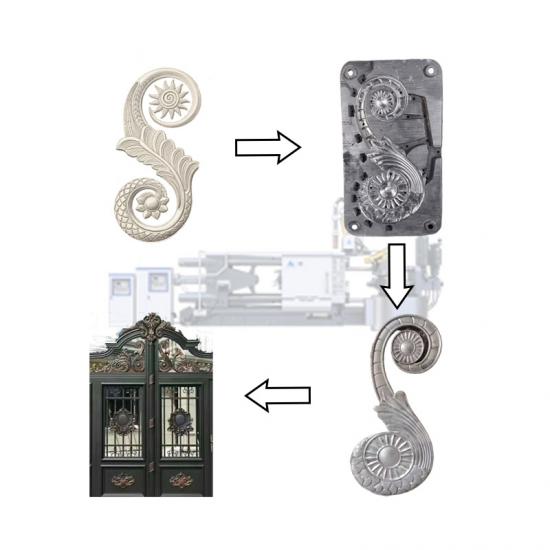

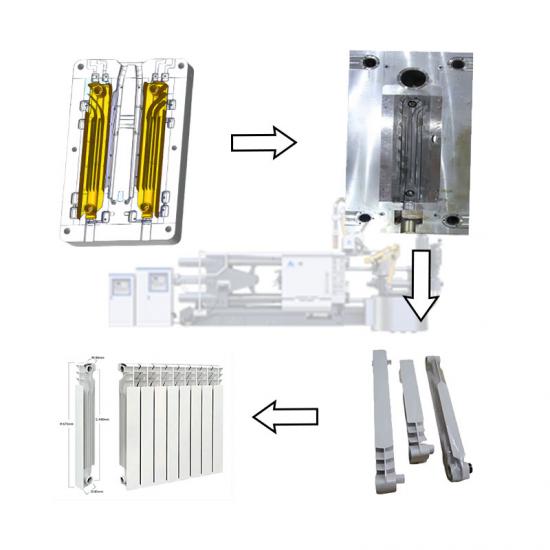

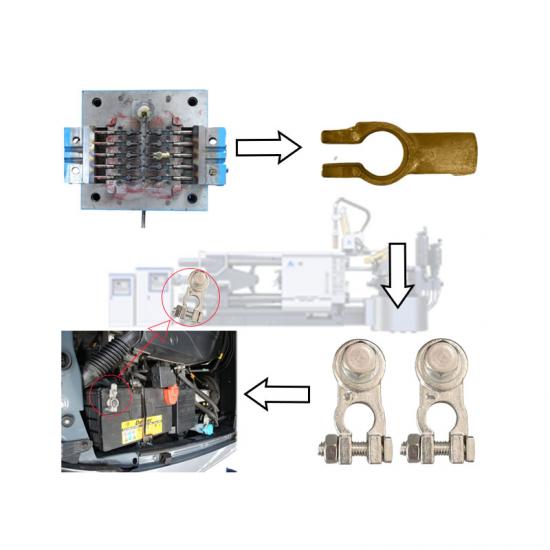

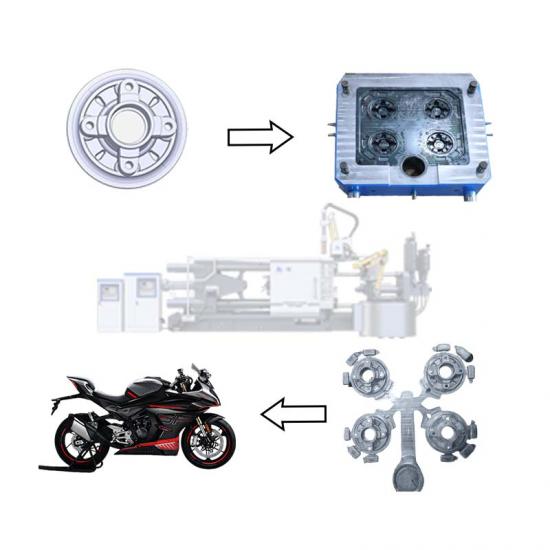

Die-cast radiator is one of the important components in the heating system manufactured using die-casting

technology, usually made of aluminum alloy or aluminum casting. The manufacturing process of these radiators

involves heating the metal to a liquid state and then injecting it through high pressure into a pre-designed mold,

ultimately forming the desired radiator product.

Here are some of the features of die-cast radiators:

1.Excellent heat dissipation performance: Die-cast radiators usually have excellent heat dissipation performance,

which can effectively transfer heat to the indoor environment and provide comfortable heating effect.

2.Sturdy and durable structure: Radiators manufactured by die-casting technology usually have a solid structure

and durable shell, which can withstand water pressure and temperature changes in the system and operate

stably for a long time.

3.Beautiful appearance design: Die-cast radiators usually have smooth surfaces and exquisite designs, which

can match various interior decoration styles and enhance the overall beauty of the indoor environment.

4.Energy saving and environmental protection: Because the die-cast radiator has good heat dissipation

performance and can efficiently utilize energy, it can reduce the energy consumption of the heating system

and achieve the purpose of energy saving and environmental protection.

5.Easy installation and maintenance: Die-cast radiators are usually easy to install and maintain, can meet

the needs of different users, and provide long-term and stable heating effects.

ABOUT US

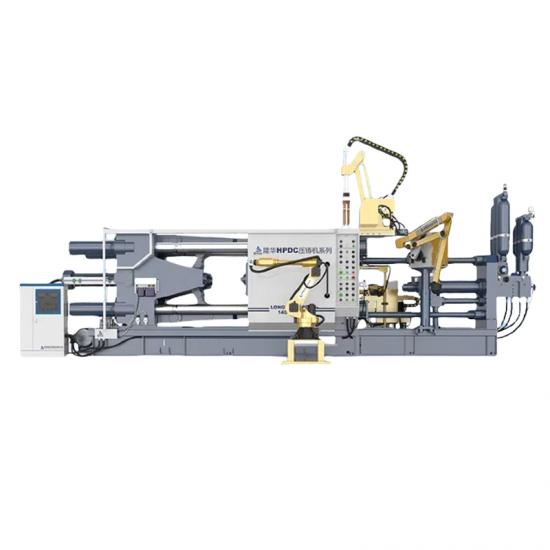

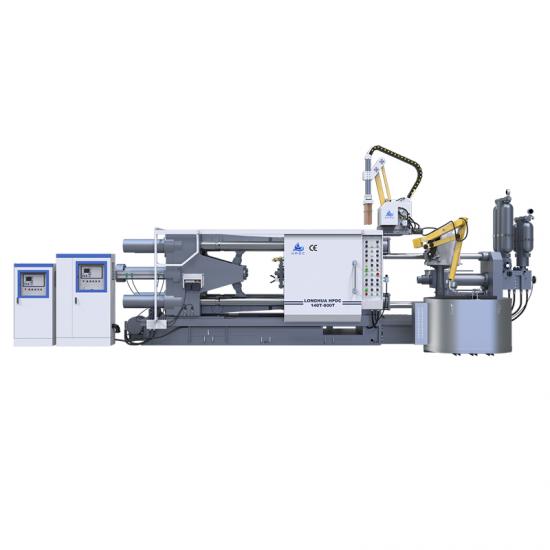

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.It

specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry

for several decades.The company focuses on research,development,production,and sales of various types

of die casting machines.The company's product range covers cold chamber die-casting machines,die-casting

manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of

different customers.