Cold chamber die-casting machine is a metal die-casting equipment with specific functions and

applications. The following are the general functions and common applications of cold chamber

die-casting machines:

Function:

High pressure casting: Cold chamber die-casting machines can apply high pressure to inject molten

metal or alloys into molds to form the required parts or products.

Temperature control: Compared with hot chamber die-casting machines, the injection system and mold

of cold chamber die-casting machines are at lower temperatures, which helps to quickly solidify molten

metal in a shorter period of time.

Suitable for low melting point materials such as aluminum alloys: Cold chamber die casting machines

are often used to process low melting point metals or alloys, such as aluminum alloys.

Production of high-precision parts: This type of die-casting machine is usually used to manufacture

high-precision, high-strength metal parts because its process can maintain small dimensional deviations.

Application:

Automotive industry: Cold chamber die-casting machines are commonly used in automotive

manufacturing, producing engine components, body structural components, etc.

Electronic products: used in the production of electronic equipment casings, heat sinks, and

other metal components.

Aerospace industry: suitable for producing key components of aircraft and spacecraft, such as engine

parts, fuselage components, etc.

Industrial component manufacturing: used to manufacture metal components for various industrial

equipment, such as pump bodies, valves, gears, etc.

Overall, cold chamber die-casting machines have a wide range of applications in manufacturing high-quality

and high-strength metal components, especially for products that require high precision and complex shapes.

| LH series of standard parameter table (330 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 3300 |

| Opening stroke | mm | 460 |

| Die thickness(Min--Max) | mm | 250~750 |

| Space between tie bars | mm | 600*600 |

| Ejector stroke | mm | 110 |

| Ejector force | KN | 160 |

| Injection position(0 as center) | mm | 0,-160 |

| Injection force(intensification) | KN | 360 |

| Injection stroke | mm | 480 |

| Plunger diameter | mm | ¢50 --¢80 |

| lnjection weight(aluminum) | Kg | 3.8 |

| Casting pressure (intensification) | MPa | 184/127/96 |

| Max. casting area(40Mpa) | CM2 | 865 |

| Injection plunger penetration | mm | 180 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 18.5 |

| Dimensions (L*W*H) | m | 6.8*1.8*2.7 |

| Machine lifting reference weight | T | 14.5 |

| Oil tank capacity | L | 800 |

will not be changed without notice)

ABOUT US

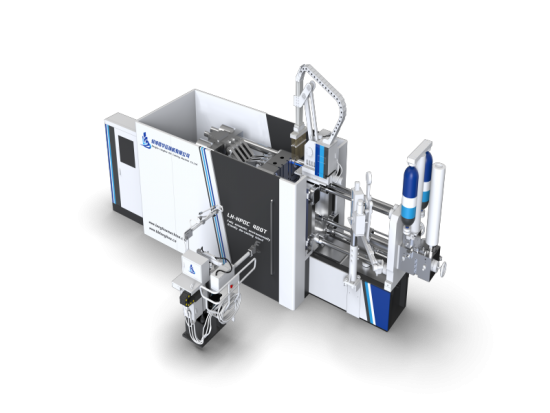

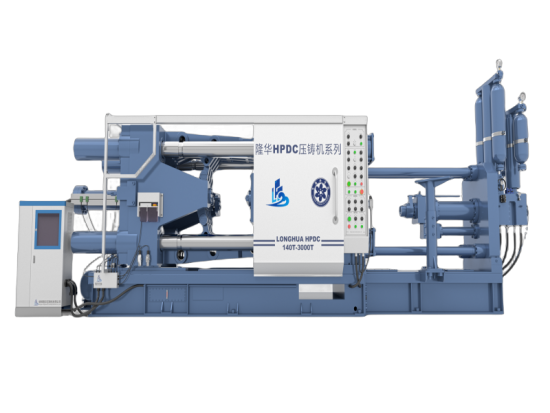

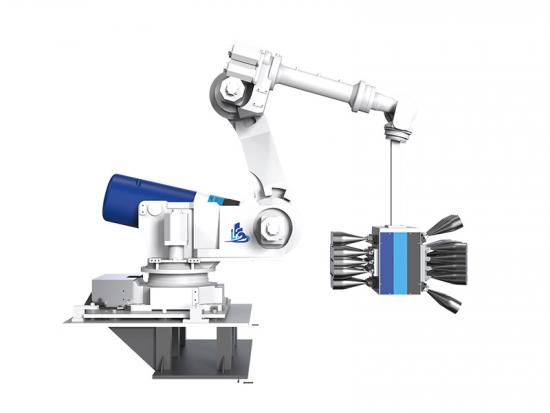

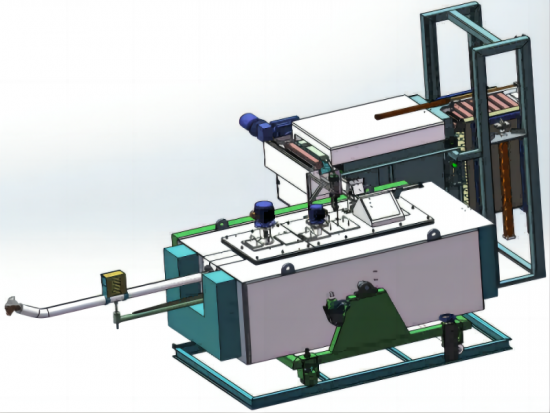

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,

China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting

industry for several decades.The company focuses on research,development,production,and

sales of various types of die casting machines.The company's product range covers cold chamber

die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of

die-casting machines to meet the needs of different customers.