Feature

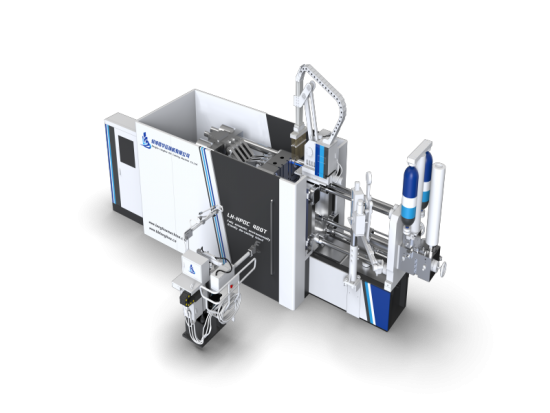

Features of cold room die -casting machine:

1. Independent metal melting and injection system: The metal melting and injection system of the cold room

die -casting machine are separated. After the metal is heated in the melting room, the metal is transported to

the injection room by pressure, and then injected into the mold for molding. This design is conducive to

reducing the time when the metal stays in the system and reduces oxidation and metal loss.

2. Suitable for high -melting point metals: Cold room die -casting machines are suitable for metal with higher

melting points, such as aluminum alloy, copper alloy, etc., because these metals need higher injection pressure

and temperature to achieve good liquidity, and cold room die casting can be achieved, and cold room die

casting can be achieved. The design of the machine can meet this needs.

3. High -pressure injection system: The injection system of cold room die -casting machines can usually

provide high injection pressure, which can ensure that the metal is fully filled and firmed in the process

of filling the mold, thereby ensuring the quality and integrity of the molding parts.

4. Reduce the generation of gas and oxidation: Due to the separation of the metal melting and injection

system of the cold room die -casting machine, the short residence time in the melting room is reduced

in the melting room. quality.

5. Energy -saving and environmental protection: Cold room die -casting machines usually use

energy-saving design. Optimized heating systems and cooling systems can reduce energy consumption.

At the same time, the reasonable utilization of energy can be achieved by circulating use of waste heat,

thereby reducing production costs and environmental pollution.

| LH series of standard parameter table (1600 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 16000 |

| Opening stroke | mm | 1200 |

| Die thickness(Min--Max) | mm | 500~1400 |

| Space between tie bars | mm | 1250*1250 |

| Ejector stroke | mm | 250 |

| Ejector force | KN | 570 |

| Injection position(0 as center) | mm | -175,-350 |

| Injection force(intensification) | KN | 1298 |

| Injection stroke | mm | 930 |

| Plunger diameter | mm | ¢110-¢150 |

| lnjection weight(aluminum) | Kg | 30.8 |

| Casting pressure (intensification) | MPa | 174/32.3 |

| Max. casting area(40Mpa) | CM2 | 4000 |

| Injection plunger penetration | mm | 360 |

| Diameter of pressure chamber flange | mm | 260 |

| Height of pressure chamber flange | mm | 30 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 37*2 |

| Dimensions (L*W*H) | m | 12.2*4.7*4.6 |

| Machine lifting reference weight | T | 95 |

| Oil tank capacity | L | 3000 |

(Due to the continuous progress of science and technology,the picture,parameter configuration,etc.

will not be changed without notice)

ABOUT US

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.

It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for

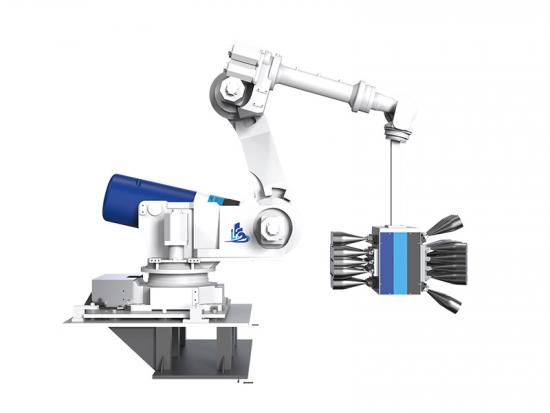

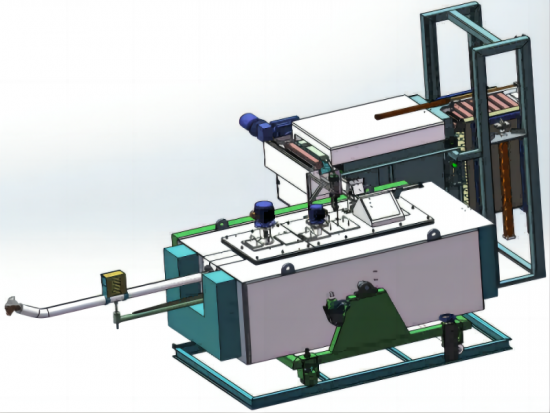

several decades.The company focuses on research,development,production,and sales of various types of

die casting machines.The company's product range covers cold chamber die-casting machines,die-casting

manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of

different customers.

CE certificate