Product Details

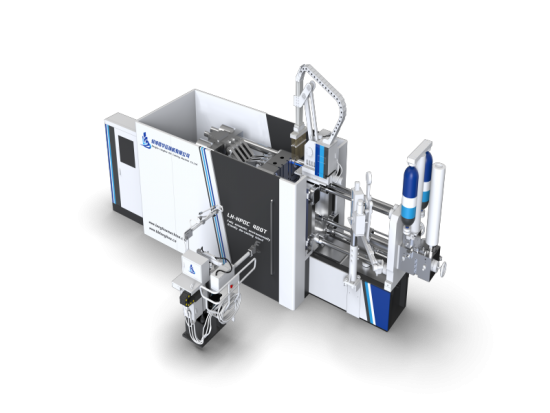

The LED lamp shell die -casting machine has the characteristics of high precision, high efficiency, high

automation, energy saving and environmental protection, and can meet the needs of product quality,

production efficiency and environmental protection requirements in LED lamp manufacturing.

Feature

Compared with other types of die -casting machines, LED lamp shell die casting machines

have some characteristics:

1. High -precision mold design: LED shells usually require precise appearance and size

requirements. Therefore, LED lamp shell die casting machines are usually equipped with

high -precision mold design and manufacturing to ensure that they produce products that

meet the requirements.

2. Optimized injection system: LED lamp shells usually have complex structure and detailed

texture. Therefore, the LED light shell die -casting machine is equipped with an optimized

injection system that can achieve high -speed and uniform metal liquid filling to ensure that

the surface of the product is smooth and no bubbles. ,No defects.

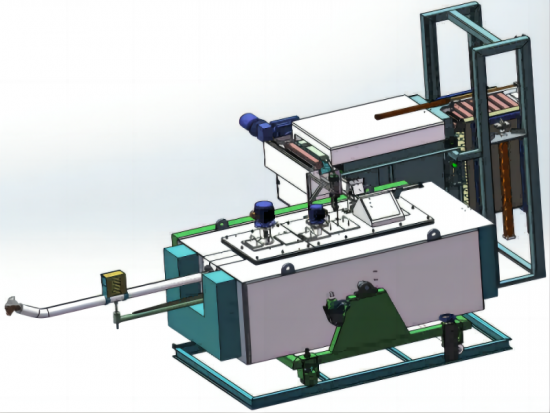

3. Efficient cooling system: During the die casting process of LED shells, it is necessary to

quickly cool down to ensure production efficiency and product quality. LED lamp shell die

casting machines are usually equipped with an efficient cooling system that can quickly cool

and solidify metal liquids to improve production efficiency.

4. High degree of automation: LED lamp shell die casting machines usually use an automated

control system to achieve automated production processes, including automatic materials,

injection, cooling, and molding, which improve production efficiency and production stability.

5. Energy -saving and environmental protection: LED lamp shell die casting machines are

usually designed with energy -saving design. By optimized heating systems and cooling systems,

energy consumption is reduced. At the same time, environmentally friendly materials and

processes are used to reduce the impact on the environment.

6. Flexible production capacity: LED shell die -casting machines usually have strong production

adaptability, can meet the production needs of different models and specifications of LED

shells of different models, and achieve flexible production switching and adjustment.

Specification

| LH series of standard parameter table (1000 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 10000 |

| Opening stroke | mm | 880 |

| Die thickness(Min--Max) | mm | 450~1150 |

| Space between tie bars | mm | 1030*1030 |

| Ejector stroke | mm | 200 |

| Ejector force | KN | 500 |

| Injection position(0 as center) | mm | 0,-300 |

| Injection force(intensification) | KN | 882 |

| Injection stroke | mm | 800 |

| Plunger diameter | mm | ¢90----¢120 |

| lnjection weight(aluminum) | Kg | 17 |

| Casting pressure (intensification) | MPa | 138.6/78 |

| Max. casting area(40Mpa) | CM2 | 2500 |

| Injection plunger penetration | mm | 300 |

| Diameter of pressure chamber flange | mm | 240 |

| Height of pressure chamber flange | mm | 20 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 45 |

| Dimensions (L*W*H) | m | 9.3*3.9*4 |

| Machine lifting reference weight | T | 70 |

| Oil tank capacity | L | 2000 |

will not be changed without notice)

Die casting product

Die-cast lamps are lighting equipment manufactured using die-casting technology, usually made of

aluminum alloy or other metal alloys. The manufacturing process of these lamps involves heating

the metal to a liquid state and then injecting it through high pressure into a pre-designed mold to

ultimately form the desired lamp product. Here are some common types of die-cast fixtures and

their characteristics:

1.Cast aluminum lamps: Cast aluminum is one of the common materials used to manufacture

die-cast lamps. Aluminum has excellent thermal conductivity and good corrosion resistance,

making die-cast aluminum lamps suitable for various indoor and outdoor environments.

This type of lighting includes chandeliers, wall sconces, table lamps, etc.

2.Outdoor lamps: Outdoor lamps manufactured by die-casting technology are usually

weather-resistant and waterproof, and are suitable for lighting needs in outdoor environments,

such as garden lights, street lights, open-air garden lights, etc. These fixtures typically have

sturdy construction and durable housings that can withstand harsh weather conditions.

3.Decorative Lighting Fixtures: Some die-cast lighting fixtures are designed as decorative lighting

fixtures such as chandeliers, wall sconces, etc. With their exquisite appearance and unique design,

these lamps can become part of the interior decoration and enhance the overall ambience of the

space.

4.Industrial lighting: In industrial environments, die-casting technology can create durable industrial

lighting, such as workshop lights, warehouse lights, etc. These lamps usually have sturdy housings

and high-brightness lighting effects, and can meet the lighting needs of industrial production sites.

5.Energy-saving lamps: Some die-cast lamps are designed to be energy-saving lamps, such as LED

lamps. These lamps usually use high-efficiency LED light sources, which have lower energy

consumption and long life, making them an energy-saving and environmentally friendly lighting

choice.

ABOUT US

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.

It specializes in the manufacturing of die casting machines and related equipment.

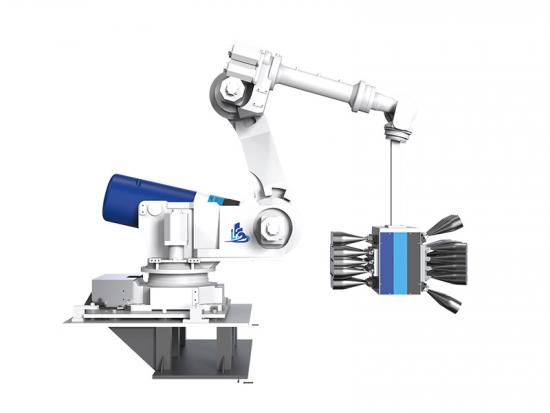

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for

several decades.The company focuses on research,development,production,and sales of various types of

die casting machines.The company's product range covers cold chamber die-casting machines,die-casting

manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of

different customers.

Why choose us

We have CE certificate