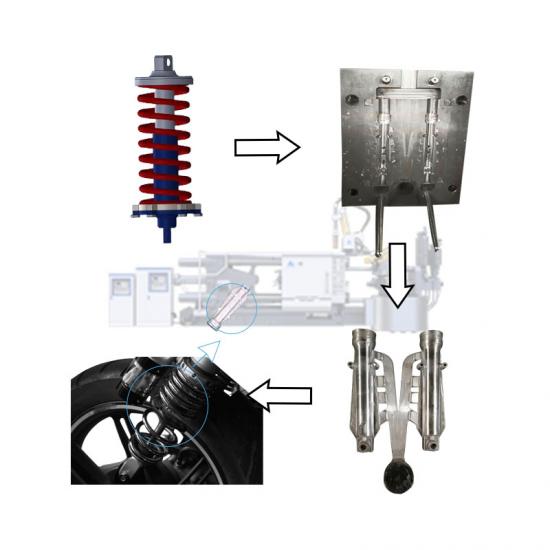

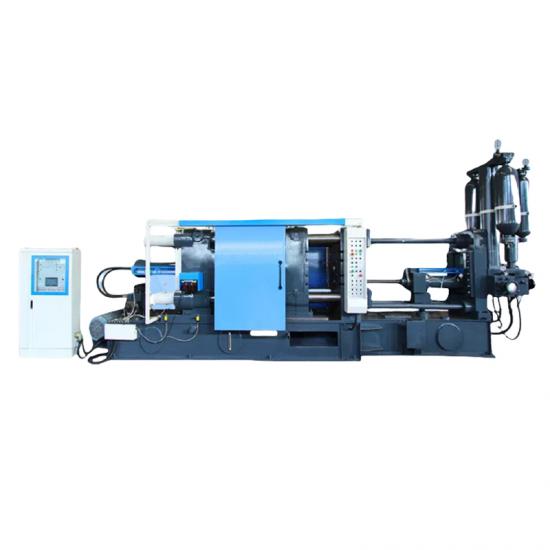

Die casting machines for motorcycle and bicycle shock absorbers have some unique features to meet the precision and performance requirements of these critical components. Here are some of the main features of these die casting machines:

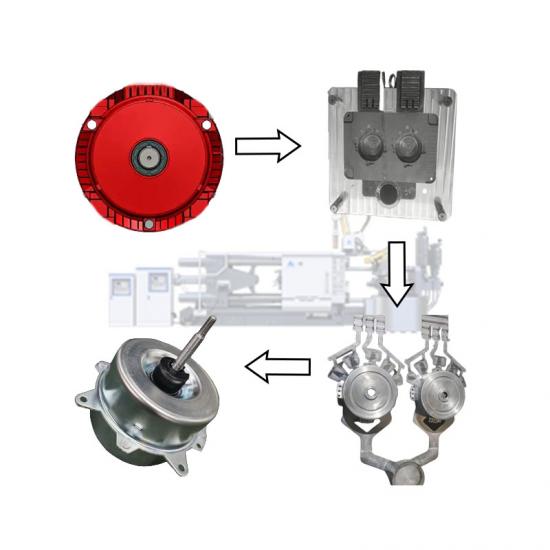

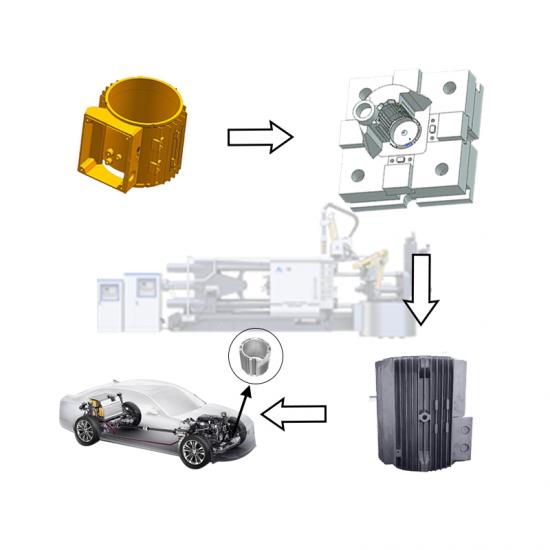

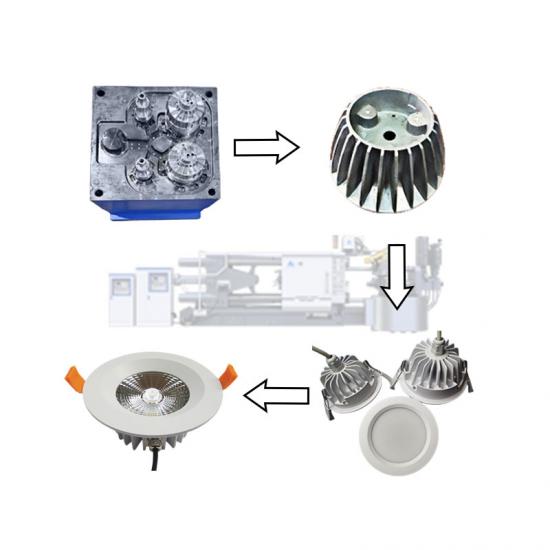

1. High precision and high quality: Shock absorbers are important components for motorcycles and bicycles, requiring extremely high precision and quality. Die casting machines need to have very high precision control to produce castings with accurate dimensions and smooth surfaces, reducing the need for subsequent processing.

2. High-pressure injection: Shock absorbers are usually made of aluminum alloy or other lightweight alloy materials, which need to be die-casted under high pressure to ensure that the metal liquid can fully fill the detailed parts of the mold and avoid defects such as pores and shrinkage.

3. Fast cycle time: In order to improve production efficiency, die casting machines need to have fast cycle times. This includes fast molten metal injection, cooling and removal processes to maximize production speed.

4. Mold temperature control: The complex shape and high-demand mechanical properties of shock absorbers require precise mold temperature control. Die casting machines are usually equipped with advanced mold temperature control systems to ensure the quality of castings and the life of the mold.

5. High degree of automation: Modern die-casting machines are usually equipped with a high level of automation systems, including automatic injection, automatic spraying, automatic picking and other functions. These automated functions not only improve production efficiency, but also reduce quality fluctuations caused by human factors.

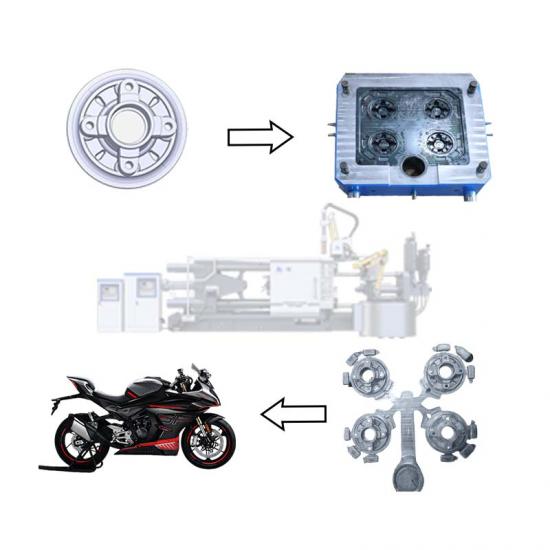

6. Multi-cavity mold design: In order to improve production efficiency, die-casting machines can use multi-cavity mold design to die-cast multiple shock absorber parts at a time. This requires the die-casting machine to have sufficient clamping force and injection capacity to handle multi-cavity molds.

7. Durability and stability: Die-casting machines need to run for a long time and at high intensity, so their structure must be very strong and able to operate stably for a long time, reducing downtime and maintenance costs.

8. Environmental protection and energy saving: With the improvement of environmental protection requirements, modern die-casting machines pay more and more attention to energy efficiency and emission control. By optimizing design and adopting new technologies, die-casting machines are able to reduce energy consumption and reduce environmental impact.

ABOUT US

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for several decades.The company focuses on research,development,production,and sales of various types of die casting machines.The company's product range covers cold chamber die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of different customers.