The main advantages of air-cooled chillers for die-casting include:

1. Self sufficiency: No external water source is required, only an external power source is

needed to operate normally.

2. Easy installation: No need for pipeline connections, reducing installation costs and construction period.

3. Wide applicability: It can be applied to various environments, especially in places without water

resources or where it is inconvenient to receive water.

4. Easy to operate: Generally equipped with an automatic control system, it is easy to operate and maintain.

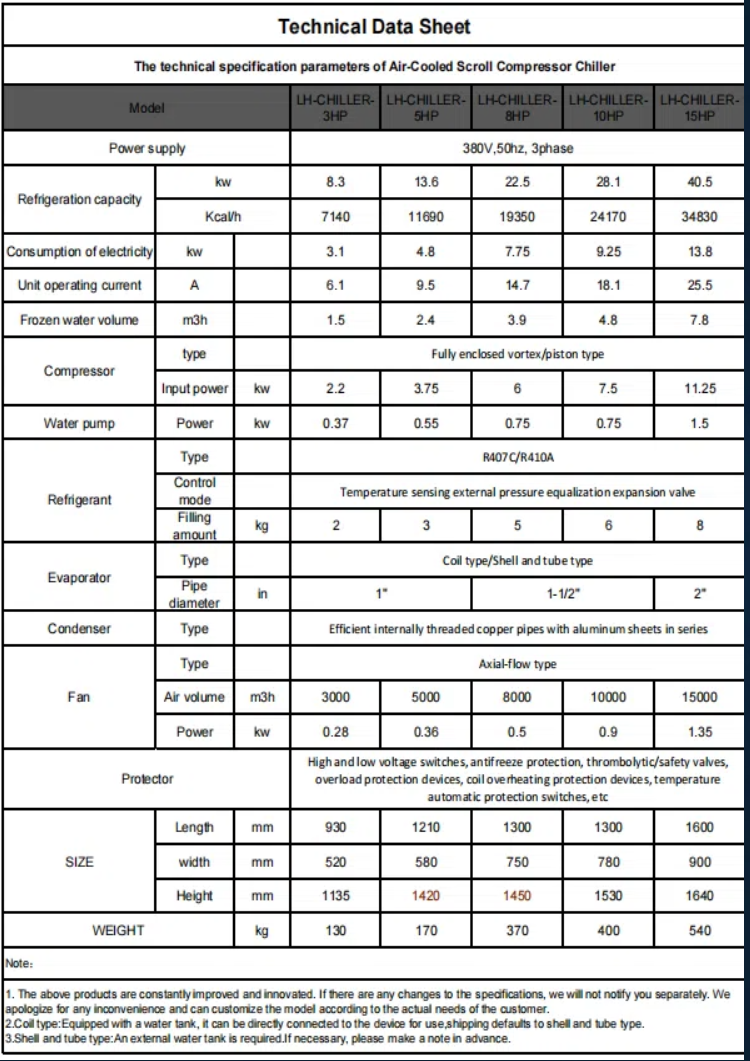

When choosing a dedicated air-cooled chiller for die-casting, it is necessary to consider the specific

requirements of the die-casting equipment, including cooling capacity, working environment, durability,

and other factors, and ensure the selection of suitable models and specifications to meet production needs.

Main Parts Description

1. Unit structure

The base is in the form of profile welding, the outer frame is formed steel, and the surface of the electric control box is treated with electrostatic spray, which is bright and clean. The adhesion, hardness and smoothness of the coating are higher than the Chinese national standard.

2. Compressor

Adopt hermetic scroll compressor, low carbon, energy saving and environmental protection; good

performance, low noise, trouble-free operation can reach more than 100,000 hours;

3. Expansion valve

The expansion valve adopts the American Emerson external balance thermal expansion valve, which can automatically adjust the refrigerant flow according to the change of the system load to achieve the automatic balance of the system operation; other main refrigeration system components such as drying filter, solenoid valve, pressure gauge, etc. International famous brand (check the Main Part List).

4. Condenser

High-efficiency copper tube-sleeved aluminum fin condenser is used, with high heat exchange efficiency and stable heat transfer performance. The refrigerant in the condenser flows in the heat transfer tube, which is convenient for maintenance and cleaning.

5. Evaporator

The evaporator adopts high-efficiency stainless steel water tank coil type. The outer surface is smooth and the cooling effect is good. The outer wall of the water tank is insulated with a 25mm thick PE insulation board, which does not condense and reduces the loss of cooling capacity. This unit uses the latest CAD design technology, CNC production and processing, compact structure and stable performance.

6. Electronic control system

The unit adopts 380V, 3-phase, 50Hz direct grounding AC system, and the voltage variation range is ±5%. The internal power cables of the unit are arranged in accordance with national safety standards. The main electrical components should be international famous brands such as Panasonic from Japan, Schneider from French, PUNP from China, DuPont and EMERSON from the United States. The computer control system of the unit automatically loads or unloads according to the change of the load to adjust the output of the cooling capacity of the unit, so that the cooling capacity is accurately matched with the actual cooling and heating load, so that the working compressor always maintains the highest efficiency state, high efficiency and energy saving.

The compressor is set to start the interval time to reduce the damage to the electrical system when starting at the same time. The control system adopts a full Chinese display controller, you can modify the setting language, which can realize remote control, and has dual protection functions of user-level password and factory-level password, which is more secure. The operating parameters of the unit can be input or modified through the display.

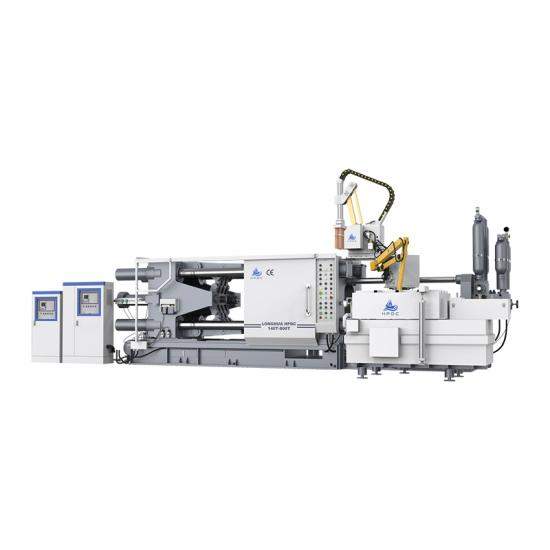

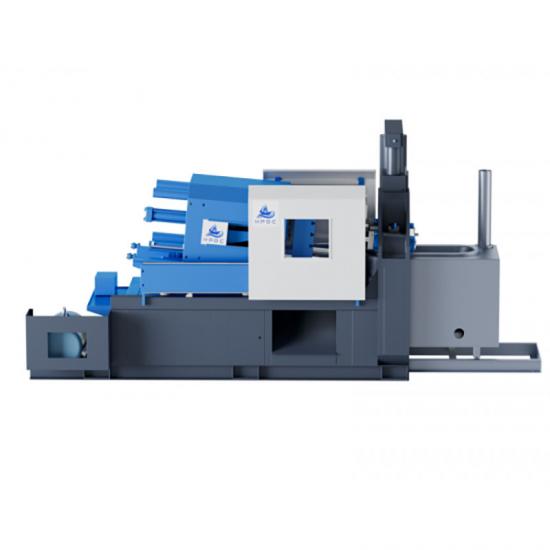

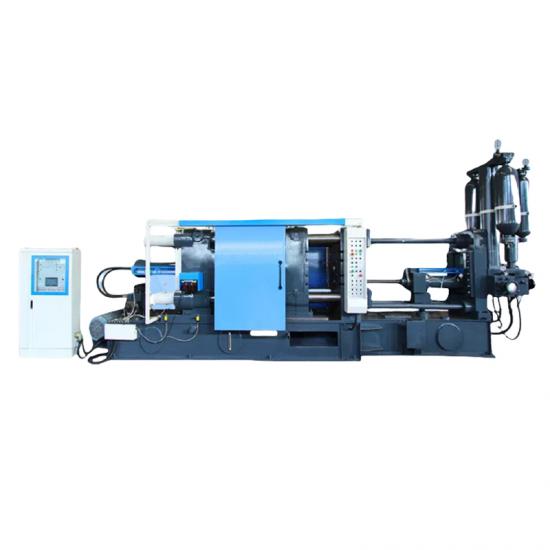

Equipment physical diagram: