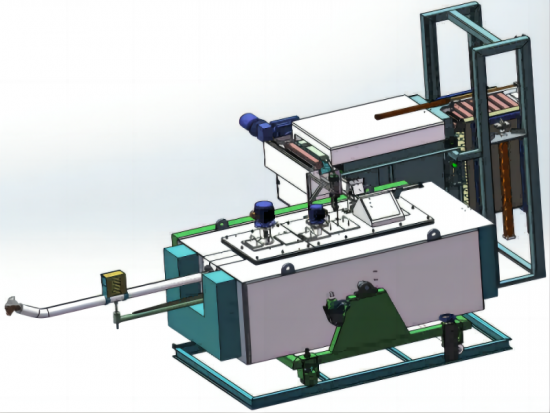

Main features of motorcycle parts die-casting machine:

High precision and consistency:

Equipped with high-precision control system to ensure the consistency of size and shape of die-casting parts.

Advanced mold design and manufacturing technology to ensure high precision and high consistency of products.

Efficient production:

Automated operating system, capable of fast cycle and improved production efficiency.

Multi-cavity mold design allows multiple accessories to be manufactured at the same time, further improving production capacity.

Material adaptability:

Can handle a variety of metal materials, such as aluminum alloy, magnesium alloy, etc., to meet the material requirements of different accessories.

Advanced furnace and pouring system to ensure the uniformity and purity of materials and improve product quality.

Durability and stability:

Made of high-strength and wear-resistant materials to ensure long-term stable operation of equipment under high pressure and high temperature environment.

Powerful structural design, capable of withstanding continuous high-intensity production.

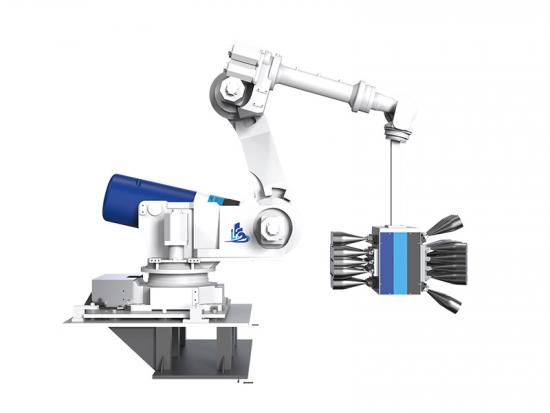

Automation and intelligence:

Equipped with automatic feeding, pouring, cooling and demoulding system to reduce manual intervention and improve production efficiency.

Intelligent control system to monitor and adjust production parameters in real time to ensure optimal production status and reduce scrap rate.

Energy saving and environmental protection:

Efficient energy utilization design reduces energy consumption and production costs.

Equipped with advanced exhaust and waste gas treatment systems to reduce environmental pollution and meet environmental protection requirements.

Safety:

A variety of safety protection devices, such as safety doors, emergency stop buttons and protective barriers, ensure the safety of operators.

Automatic detection and alarm system to timely detect and handle equipment failures and reduce safety hazards.

Easy to maintain:

Modular design facilitates maintenance and parts replacement, reducing equipment downtime.

Detailed maintenance guide and fault diagnosis system to help operators quickly solve problems.

Flexibility and versatility:

It can adapt to the production needs of motorcycle accessories of different shapes and sizes, and support rapid mold replacement and adjustment.

It is suitable for multi-variety and small batch production mode to meet the diverse needs of the market.

These characteristics enable the motorcycle accessories die-casting machine to efficiently and stably produce a variety of high-quality motorcycle accessories to meet market demand, improve production efficiency, reduce production costs, and ensure the safety and environmental protection of operation.